The 10 Types of Manufacturing Equipment You Need to Know

Table of Contents

- What Counts As Industrial Manufacturing Equipment?

- 1. CNC Machines

- 2. 3D Printers

- 3. Injection Molding Machines

- 4. Conveyor Systems

- 5. Industrial Robots

- 6. Press Machines

- 7. Laser Cutting Machines

- 8. Grinding Machines

- 9. Packaging Machines

- 10. Welding Machines

- What Are The Examples Of Industrial Machinery And Equipment?

- Conclusion

Manufacturing is the backbone of industrial and economic growth, and the right equipment is essential for efficiency, precision, and quality. This blog delves into the 10 types of manufacturing equipment every professional should understand. Whether you're starting a manufacturing business or optimizing your current production line, knowing these tools is crucial.

What Counts As Industrial Manufacturing Equipment?

Industrial equipment refers to machinery and tools used in manufacturing, production, construction, and other industrial activities. It typically includes equipment designed for tasks such as material handling, machining, assembly, and quality control. Examples include CNC machines, conveyor systems, injection molding machines, industrial robots, and welding machines. These tools are often categorized based on their function (e.g., cutting, forming, or assembling), and they are crucial for ensuring efficiency, precision, and safety in industrial operations.

1. CNC Machines

CNC (Computer Numerical Control) machines are vital for precision manufacturing. By automating machining tasks like cutting, drilling, and milling, CNC machines ensure unparalleled accuracy and productivity, making them indispensable in modern production lines.

Key Features:

- High precision and repeatability for machining operations

- Versatile material compatibility, including metals, plastics, and composites

- Automated processes that reduce human error and improve productivity

Applications:

- Aerospace: Turbine blades and structural components

- Automotive: Engine blocks and transmission parts

- Electronics: Circuit boards and enclosures

Industry Status:

CNC machines are widely adopted across industries due to their versatility and precision. Emerging trends include hybrid CNC systems combining additive and subtractive manufacturing.

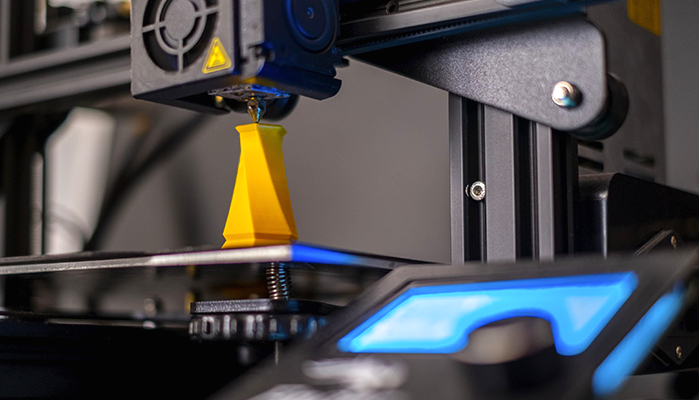

2. 3D Printers

3D printing, also known as additive manufacturing, revolutionizes how products are designed and produced. It enables the creation of complex geometries that traditional manufacturing methods cannot achieve, fostering innovation across industries.

Key Features:

- Layer-by-layer additive manufacturing process

- Customization and rapid prototyping capabilities

- Compatibility with diverse materials like plastics, metals, and ceramics

Applications:

- Healthcare: Prosthetics, implants, and surgical models

- Jewelry: Custom designs and intricate patterns

- Footwear: Customized soles and lightweight designs

Industry Status:

3D printing is a growing sector with applications expanding from prototyping to full-scale production. The industry is witnessing advancements in material science and faster printing technologies.

3. Injection Molding Machines

Injection molding machines are critical for producing high-volume plastic parts with intricate designs. These machines deliver speed and consistency, making them ideal for mass production.

Key Features:

- High-speed production for complex shapes

- Suitable for mass production with consistent quality

- Works with a variety of thermoplastics and resins

Applications:

- Consumer Goods: Bottles, containers, and toys

- Automotive: Dashboard panels and bumpers

- Medical: Syringes and IV components

Industry Status:

Injection molding remains a cornerstone of manufacturing for plastic products. Current trends include the use of bio-based polymers and automated systems for enhanced efficiency.

4. Conveyor Systems

Conveyor systems streamline material handling across production stages. These systems are essential for improving operational efficiency and reducing manual labor.

Key Features:

- Efficient material transportation between production stages

- Customizable for various layouts and item sizes

- Integrated with sensors for automation and monitoring

Applications:

- Food and Beverage: Transporting packaged goods

- E-commerce: Order fulfillment and distribution centers

- Pharmaceuticals: Moving medications and medical supplies

Industry Status:

Conveyor systems are integral to modern assembly lines. Innovations include energy-efficient motors and modular designs for flexibility in manufacturing.

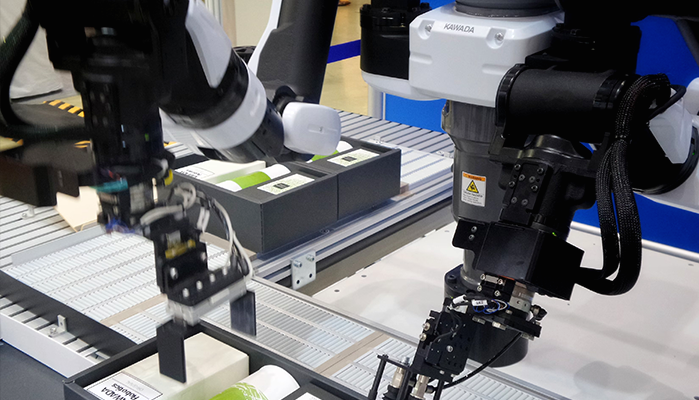

5. Industrial Robots

Industrial robots are at the heart of automated manufacturing. They perform repetitive tasks with unmatched speed and precision, significantly improving productivity and safety.

Key Features:

- High precision and speed in repetitive tasks

- Programmable for diverse manufacturing applications

- Enhanced safety features for human-robot collaboration

Applications:

- Automotive: Welding, painting, and assembly

- Electronics: Circuit assembly and soldering

- Aerospace: Composite material handling and drilling

Industry Status:

The robotics sector is rapidly evolving with the rise of collaborative robots (cobots) and AI-driven automation. Small and medium-sized enterprises are increasingly adopting robots for scalability.

6. Press Machines

Press machines are fundamental in shaping and forming materials. Their ability to handle high-strength materials makes them essential in heavy-duty manufacturing sectors.

Key Features:

- Compression-based forming and shaping processes

- Types include hydraulic, mechanical, and pneumatic presses

- Capable of handling high-strength materials

Applications:

- Automotive: Chassis components and body panels

- Aerospace: Forming lightweight alloys

- Construction: Structural steel and metal fittings

Industry Status:

Press machines are crucial for heavy-duty manufacturing. Current advancements include smart presses with real-time monitoring and energy-efficient hydraulic systems.

7. Laser Cutting Machines

Laser cutting machines are indispensable for precision manufacturing. Their ability to cut intricate designs with minimal waste makes them ideal for high-value applications.

Key Features:

- High-precision cutting with minimal material waste

- Suitable for intricate designs and fine details

- Works on a variety of materials, including metals, plastics, and wood

Applications:

- Jewelry: Intricate patterns and unique designs

- Automotive: Custom metal parts and decorative trims

- Electronics: Circuit board fabrication

Industry Status:

Laser cutting is a staple in precision manufacturing, with advancements focusing on faster lasers and reduced operational costs. Fiber laser technology is leading the market.

8. Grinding Machines

Grinding machines are essential for achieving superior surface finishes and dimensional accuracy. These machines are vital in industries requiring high precision.

Key Features:

- Removes material for a smooth surface finish

- Accommodates various shapes, from flat to cylindrical

- High accuracy for machining hardened materials

Applications:

- Tool Manufacturing: Sharpening and grinding tools

- Automotive: Engine parts like crankshafts and camshafts

- Construction: Polishing and finishing structural materials

Industry Status:

Grinding machines are essential in precision industries. Automation and CNC integration are reshaping the sector for higher efficiency and better consistency.

9. Packaging Machines

Packaging machines ensure consistency, speed, and quality in packing processes. These machines are pivotal for industries focused on branding and sustainability.

Key Features:

- Automates filling, sealing, and labeling processes

- Ensures consistency and reduces manual labor

- Supports sustainable and eco-friendly packaging solutions

Applications:

- Food and Beverage: Bottling, sealing, and labeling

- Pharmaceuticals: Blister packs and dosage labeling

- Cosmetics: Tubes, jars, and cartons

Industry Status:

The packaging industry is shifting towards greener solutions, with machines designed for recyclable materials and reduced energy consumption. Smart packaging with QR codes is gaining popularity.

10. Welding Machines

Welding machines are indispensable for joining materials in construction and manufacturing. Their versatility makes them suitable for a wide range of applications.

Key Features:

- Joins materials using heat, pressure, or both

- Types include MIG, TIG, and Stick welding machines

- Suitable for diverse materials, including metals and plastics

Applications:

- Construction: Structural steel and pipelines

- Automotive: Chassis and exhaust systems

- Shipbuilding: Hull construction and repairs

Industry Status:

Welding machines are advancing with the inclusion of robotics and AI for precision welding. Portable and energy-efficient welders are also gaining traction in the market.

Examples of industrial machinery and equipment span various industries, including manufacturing, construction, agriculture, energy, and more. Below is a categorized list:

What Are The Examples Of Industrial Machinery And Equipment?

1. Manufacturing Machinery

- CNC Machines: Lathes, milling machines, and routers for precision shaping and cutting.

- Assembly Line Equipment: Conveyor belts, robotic arms, and pick-and-place machines.

- Injection Molding Machines: For producing plastic parts.

- Printing Machines: Offset printers, screen printing machines, and digital textile printers.

- Welding Machines: MIG, TIG, and arc welders for joining metals.

- Laser Cutters: Used for precise cutting and engraving of materials.

- Packaging Equipment: Shrink-wrapping machines, labeling machines, and filling machines.

2. Construction Equipment

- Earthmoving Machinery: Excavators, bulldozers, and backhoes.

- Lifting Equipment: Cranes, hoists, and forklifts.

- Paving Machines: Asphalt pavers and road rollers.

- Drilling and Blasting Machines: Used in mining and tunneling.

- Concrete Mixers and Pumps: For handling and transporting concrete.

3. Agricultural Machinery

- Tractors: Multipurpose vehicles for plowing, tilling, and hauling.

- Harvesters: Combine harvesters for grain crops and other specialized harvesters.

- Irrigation Equipment: Sprinklers, drip irrigation systems, and pumps.

- Seeders and Planters: For sowing seeds.

- Balers: For compressing harvested crops into bales.

4. Energy and Power Equipment

- Generators: Diesel, gas, and solar-powered generators.

- Turbines: Wind, gas, and hydroelectric turbines.

- Transformers: For voltage regulation in power distribution.

- Solar Panels and Inverters: For renewable energy production.

5. Food Processing Machinery

- Mixers and Blenders: For food ingredients.

- Conveyors: For transporting food products during processing.

- Sorting and Grading Machines: For fruits, vegetables, and grains.

- Bottling and Packaging Machines: Used in beverage and food industries.

- Ovens and Fryers: For baking and cooking.

6. Textile Machinery

- Weaving Machines: For creating fabric from threads.

- Spinning Machines: For turning fibers into yarn.

- Dyeing Machines: For coloring fabrics.

- Printing Machines: Digital, screen, and rotary printers for textiles.

7. Heavy Industrial Equipment

- Kilns: For ceramics and metal production.

- Furnaces: For smelting and forging metals.

- Compressors: For air and gas compression.

- Hydraulic Presses: For shaping and forming materials.

8. Miscellaneous Industrial Equipment

- Pumps: Centrifugal, diaphragm, and peristaltic pumps for fluids.

- HVAC Systems: For climate control in industrial facilities.

- Robotics: Autonomous systems for automation.

- Testing Equipment: For quality control, such as spectrometers and tensile testers.

Conclusion

Understanding the types of manufacturing equipment is vital for selecting the right tools for your production needs. Whether you aim for automation, precision, or scalability, these 10 types of equipment form the foundation of a modern manufacturing setup. Staying informed about emerging trends and maintenance best practices ensures long-term efficiency and sustainability.

Start your borderless business here

Tell us about your business and stay connected.

Keep up with the latest from Alibaba.com?

Subscribe to us, get free e-commerce tips, inspiration, and resources delivered directly to your inbox.